Kansas City Tdi

& CoolAirVw Repair

01M Filter change

First

of all pull the skid plate.

Then

with an allen wrench remove

the drain plug.

Then

put the allen wrench up in

the hole the drain plug came out of, and remove the stand pipe. This is to drain the pan thoroughly.

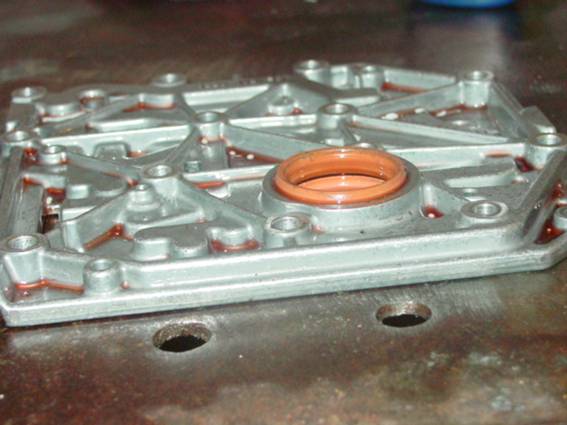

This

is what the “stand pipe” looks like after you remove it. The “stand pipe” is orange in this pic.

There

is a bracket to protect the front of the trans pan

that I didn’t get a picture of. It has

four 16mm bolts. Remove it to get

access to the front two pan bolts.

Then

use a 10 mm socket to pull out the 4 pan bolts.

Then

you’ll see the filter. Just grab it and

pull it off. Sometimes you may find it

sitting in the pan. Don’t worry, the pan

holds it in place, and it just fell out when you removed the pan.

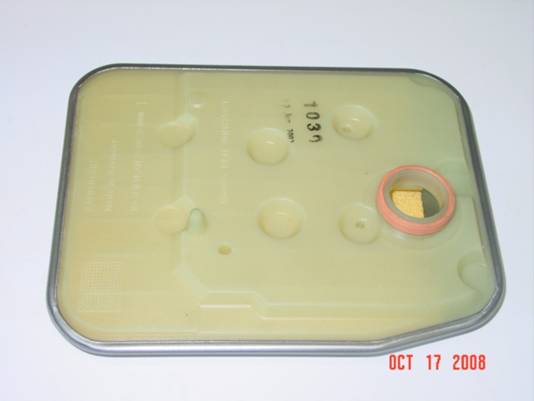

When

you pull the filter out, usually the filter seal (orange) will stay inside the

valve body. Pry it out with a

screwdriver.

Don’t

forget to remove your old filter seal or you’ll end up with two of them in

there. This was a valve body someone

shipped to me and whoever serviced it before just shoved the new filter up in

there with the new seal and left the old one in there too.

Make

sure your new filter comes with a filter seal then seat it up in the valve

body. Clean the pan out thoroughly.

In

my hand are the “torque limiters” (spacers) that go inside the holes that the

pan bolts pass through. They limit the

amount of crush on the pan gasket. Some of

the new gaskets do not come with them so you must change them over into the new

gasket. To do this just sit the gasket

on a hard surface, sit the spacer on the hole then shove it in with the handle

end of a screwdriver. A little lube

doesn’t hurt either. If you leave these

out the pan will leak.

Here’s

a new gasket with no spacers in it.

Here’s

one in the pan gasket

Break

open the filter. They are real good at

trapping broken pieces. The pump suction

pulls stuff up in there. So if you don’t

break it open you might be missing some “evidence” of damage. This one the trans

is shot!

Also

take a good look into the pan. Use a

flashlight to look for metal or clutch material. This one has a broken chunk, but notice the fine metal in the bottom where there is no

fluid. This trans

is shot even without the chunk.

Expect the fluid to be dark. This just means it needs changed, but if its

burnt, then you may have some clutch damage inside the

trans. See failure analysis for clutch

damage pics.

Expect

the magnet to have a little fuzz on it.

This trans was Ok, it just needed a little luvin’ on the valve body.

Well

if you get the filter seal out, put a new filter in with a seal on it, put the

torque limiters into the new gasket, seat the gasket on the pan properly

(meaning even), then tighten the pan, by hand.

Understand that over tightening the pan bolts will not crush the gasket

more. All over tightening will do is rip

the threads out of the case which will then necessitate installing a heli-coil in the pan bolt hole. So tighten till the torque limiter is squeezed

then go about 1/8 turn more.

Reassemble

as you took it apart then follow the correct fill sequence.

In

the lower left you see the fill tube. Its accessed from under the car. To get to it you’ll have to have the belly

pan/skid plate off, then remove the protective bracket

at the front of the trans, then break the red cap off. You’ll need a new red cap. Then you’ll need some kind of pump to pump the

fluid up into the fill tube or a funnel with a hose on it to pipe it down to

the fill tube.

All

this is very annoying to me so I fill this trans

through the g38 hole.

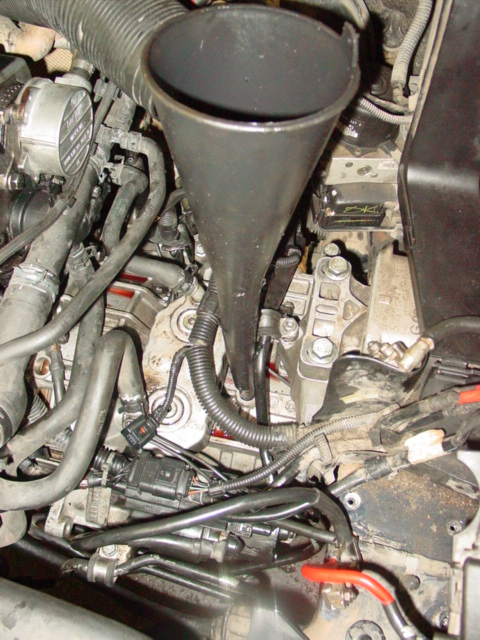

To

fill through the G38 hole just remove the breather, then remove the bolt to the

sensor and pull out the G38. No need to uplug it, but don’t yank on the wires. Use a long pair of needle nose or just work

it out gently with your hands.

Then

using a long “transmission style” funnel, then pour in the fluid.

The

battery is out in this pic but it doesn’t need to be.

FILL PROCEDURE

It’s

slightly different than you might find elsewhere. OEM procedure isn’t wrong but it’s confusing

and lots of folks end up slightly low.

With

filter change you’ll need 3 liters but its best to have 4 on hand just in case. With valve body change you’ll probably need 4

liters but its best to have 5 on hand just in case. Quite a bit of the converter fluid will drain

out when the valve body is pulled. Complete fill will empty trans

and empty converter is 5.3 liters according to the “book”. A used trans will

never be empty though. I

1.

Car must be cold,

and level. I do this on the ground.

2.

After pan drop

install filter and stand pipe. Then put

check/drain plug in a few turns by hand.

3.

Pour in 3 liters

4.

Install scan

tool, turn key on and get scan tool communicating with trans

computer.

5.

Start engine

6.

Pull up data for trans temp.

7.

If trans was just replaced then put in another 3 liters. If you just serviced it then pull check plug

and immediately reinstall it. If fluid doesn’t

come out add another 1/2 liter. The pump

will be filling the converter with fluid from the pan and you don’t want the

pan to run dry. I use a small shallow

pan to keep fluid from running on the floor.

8.

When data shows

35 degrees Celsius then pull check plug. Allow fluid to drain out till it is not a

steady stream anymore. Meaning when if

starts “glugging” instead of running out in a steady

stream, then reinstall the plug and tighten it.

#8

is where I think folks go wrong. They

leave the check plug out till fluid stops running out and this makes the trans slightly low.

What you need to understand is that there are fluid pressure exhausts on

the valve body and spinning components in the main body of the trans. Both of these

will throw fluid into the pan making waves and splashes. So the fluid will continue to drip out even

when fluid is low, below the stand pipe.

The waves and splashes make fluid keep coming out. Don’t do

this. Watch for the first “glug” then plug it.

If

you used my method of top filling through the G38 it’s likely you triggered a

MAF code, so clear it and reassemble the top and your done.

Be

sure to see our 01m FAQ