Kansas City Tdi & CoolAirVw Repair

01M Valve Body Repair

In times past, when rebuilding the 01M,

you just ordered a new Valve Body from VW for about 700 dollars, because there were

no methods to test, nor were there techniques or parts available to repair or

rebuild them.

Fortunately now I’m equipped to vacuum

test for wear and to repair these by boring oversize, and installing new

valves. I’ve been recording my findings,

to find patterns of wear and have identified several common problems where this

repair can be a good fix.

01M Valve Bodies are notorious for wearing

out the bores. So much so that a training video I watched used the 01M as its

primary example. This wear is the

starting point for many catastrophic failures.

Minor wear could cause 01192 (P0740) codes or TCC surging. Get it fixed before it destroys your whole

transmission.

Other wear causes low pressure that can

cause soft shifts, delayed engagement, flares on shifts and killing the

engine. The main pressure regulator can

wear causing uncontrollable line pressure which makes harsh shifts of or harsh

engagements. Some wear can cause

slipping and P0740 00652 codes sometimes.

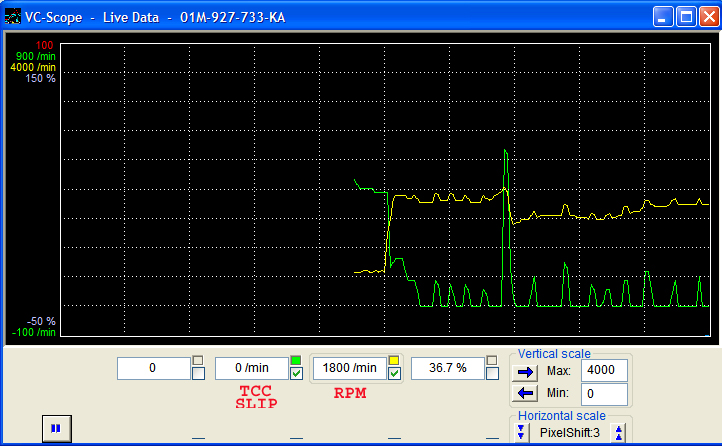

Here’s a video of a TDI Beetle with the

TCC surging. Most people would think

this was “shifting back and forth”, but it’s not really correct to say shifting

with regard to the TCC. Pay attention to

the movement of the tach and the tone of the motor and you will notice it surging

in and out.

Click

this picture to view video.

Click

this picture to view video.

Vag-com’s graphing feature

shows the surging very well.

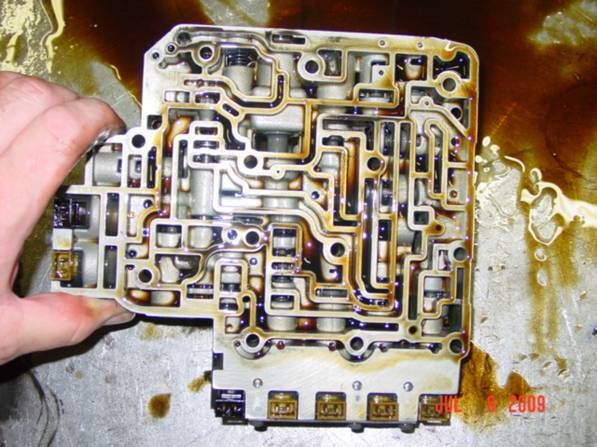

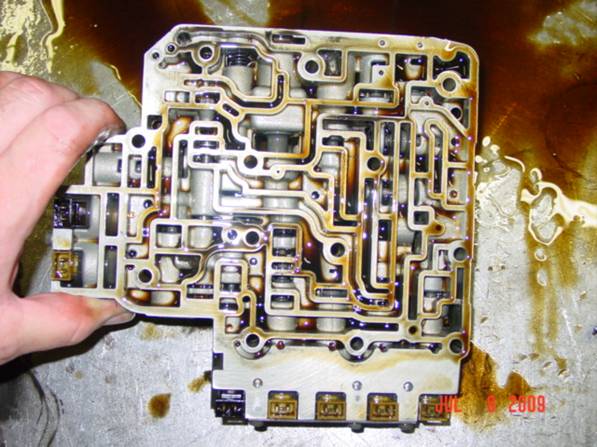

Ribbon strips have a lot of

problems usually triggering solenoid codes.

Be careful handling them, or you’ll get a solenoid code as your

reward. I sell a plastic 3373 tool that

helps prevent the harness from breaking.

Its 13.00 shipped. It’s a good

idea to get one of these because it’s cheaper than a harness.

See my 01M FAQ for “How-To”

remove the 01M valve body.

Valve body repair charges are based on how much your

valve body needs. Most valve bodies

I’ve tested have similar wear patterns, so they’re usually the same price,

about $360.00

If you need these services please contact me. Contact info

It’s possible

yours could have additional problems, resulting in higher expense. $360

includes….

Thorough cleaning.

Complete

disassembly with ALL valves removed.

Checking Valve body for warpage.

Visual inspection of ALL valves.

Here’s an

animated pic of a worn valve as I rolled it.

Mechanical

checks that ALL valves are not sticking.

Boring valve body to accept oversize.

Installing

oversized valves.

Retest replacement valves for ability to hold vacuum.

Clean and Ohm

check solenoids.

Mechanical check of solenoid function.

Amp draw check on solenoids.

Shipping is

usually 22.00 round trip inside the continental USA.

I

also can provide you with filter and pan gasket for $29.00 (no extra shipping).

If you need solenoids I have them in stock also.

Any common problems I

should try to avoid while removing the valve body?

- Be very careful removing the harness. If the “locks” break off then you should

replace the harness. I can provide

this. These things wiggle loose and

trigger solenoid codes and failsafe if the locks are broken. I have a plastic 3373 harness removal

tool that I sell for 13.00 shipped.

It’s a good Idea to get one of these before taking your valve body

off because this may help you avoid breaking the harness. Just e-mail for details.

- When replacing your pan gasket, make sure there are

spacers in the gasket, where the bolts are. If not, then take the spacers out of

then old gasket and put it in the new.

- There is a small torx that bolts the manual valve

“link” to the shaft that moves it.

Take the torx bolt out and pull the manual valve gently out of the

valve body. This will need adjusted

when you go back together. I’ll

give you the adjustment in the form of a printed bulletin when I send the

valve body back.

What

warranty is on a valve body?

Here's

the big disclaimer. Valve body repair is

for 01192 code or surging TCC.

Wear in the valve body leaks the TCC apply pressure. Therefore TCC apply pressure "falls" into the pan instead of going to the TCC to apply the clutch. There are other areas in the trans that can leak the exact same pressure. (ie the pump, the stator bushings or the TCC itself) There are no techniques short of removal and disassembly of the entire transmission that can pinpoint where the pressure leak is, that causes your surging or 1192 code. Therefore, there is no warranty that this "repair" will fix your surging or code, nor is there any guarantee’s on how long your trans will last, nor is there any guarantees the surging wont reoccur, nor is there any guarantees the some other area of the trans, as mentioned before wont fail in the future and cause a 01192 code. Also, I mentioned testing the solenoids. There is no warranty on a tested solenoid.

That

being said, 99% of the valve bodies that I have done have fixed the TCC code or the

surging.

Problems with your valve body that make it unrebuildable.

Other valve body rebuilders, and other valve body related rants.

As of this writing I have done about 120 of these valve bodies and I've seen several valve bodies that were done by other rebuilders. Not one of these had all the valves replaced, most of them only had one valve replaced. And, all of them had significant wear on the valves that were not replaced. Currently with my testing procedures I find significant wear on all 4 of the valves that are available, and this wear is corrected when I'm done with it.

I have to admit when I first started doing these I didn't replace all the valves (defined as all the valves that commonly wear or all the valves that are available to be replaced). This was because as I tested them they didn't check bad, but this was only due to my testing techniques being inadequate at the time. I spoke to one of my competitors during a time when I received a defective reamer and was ruining every valve body I worked on, and he said, "we dont replace that valve", so I said, "Every one I check has significant to major wear", and he said, "Aw hell, If we put in on the machine and it works then we ship it." To this I say, "just because it works doesn't mean its ok. It could wear just slightly more and then start "not working".

My testing procedures have evolved over time, and now I know I ship out a quality product. Early on I was using a technique as shown on a training video that I aquired and this was why I was not replacing one valve. Later I learned that the testing they were recommending didn't show the wear in one land and I had to develop my own technique for finding the wear on this valve.

Be

sure to see our 01m FAQ